NIG assists its clients in achieving planning reliability, optimal production conditions, maximum machine usage potentials and maintenance that conserves resources. The service teams use maintenance check lists and preventative repairs of the entire machinery in low production phases to secure continuous readiness for use.

SERVICE

We Guarantee:

Planned upkeep

Regular maintenance by check list

Preventative maintenance

Optimised resource usage

Reference

Industry:

Producer in metal processing industry

Project type:

Regular service and maintenance activities

We are very satisfied. The project implementation is repeated four times per year in a flexible and client-focused manner.

Description

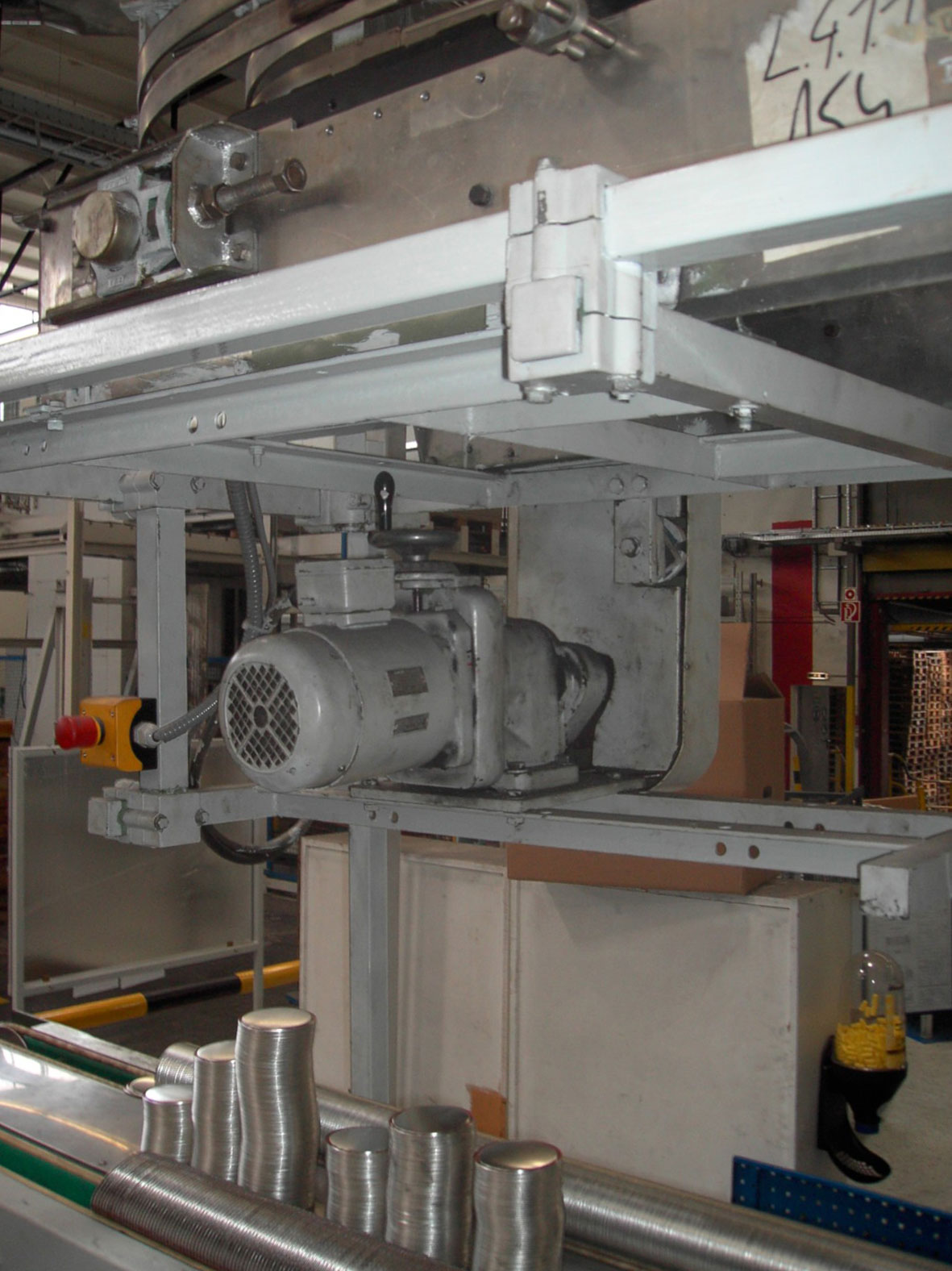

Regular and recurring service, maintenance and repair activities for defined series of machinery and plants for processing of metallic raw materials.

Mechanical disassembly of motors, rollers, belts and bearings including maintenance, repair or replacement of parts and subsequent reassembly.

Provision of necessary tools and consumables as well as ordering of necessary parts based on actual work done.

Documentation of completed tasks and repairs in records provided by the client.

Duration:

1 week // repeating

Staff:

Up to 8 skilled technicians

Assembly supervisor and industrial mechanic